|

¡¡

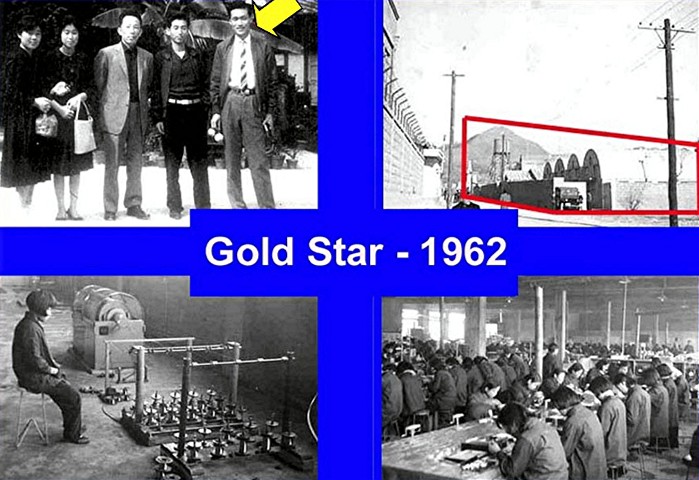

The

days of Gold Star

After

graduating from

Seoul

National

University

in September 1958, I wandered around here and there for about 2 years in

Seoul

until I finally got a job at Gold Star Company in Sep. 1960 by pulling a few

strings from Mr. Seung-Chan Park, Executive Director of Gold Star Co. and my

second brother-in-law¡¯s youngest brother.

I

think the Gold Star at the time, which had Lucky Chemical as a holding

company, was only three to four years old.

The company was located in Yeunjidong, Busanjingoo,

Pusan

city, where Lucky Chemical was located on the opposite side cross the

street. In

order to find the company, one had to pass by the American military camp

called ¡°Hayaria¡± and follow a long narrow road to Yeunjidong.

I

assume now that there were less than a thousand workers including girl

operators at Gold Star at that time. It was the first electronics company in

Korea

producing radio sets. A witty friend of mine even sent me a letter with the

address written ¡°The place where Gold Star radios are made in

Pusan

,¡± and it was really delivered to me.

However,

because it was the first production of radio sets in

Korea

without any help from other countries, it was really difficult to produce

radios in

Korea

with inexperienced college graduated engineers who learned theory only at

college. Therefore, they hired high school graduated but experienced radio

repair men at radio shops as engineers at first. This way, they could make

radio within short period without having technical alliance with

Japan

, but they could not be quality radio sets instead.

In

addition, during the 60¡¯s, we didn¡¯t have any good measuring instruments

available in the market and the only equipment we had in Gold Star were

American military surplus voltage/current/ohm meters and a few 2 inches

oscilloscopes (No one use 2 inches today. They are all 5 inches or larger

now.)

Due

to the situation, to make decision whether the quality of the radio set we

have designed or produced (sensitivity, selectivity, audio quality etc.) is

acceptable for sale or not, we had to judge the quality of the radios just

listening to a few Japanese broadcasting stations we could easily catch in

Pusan, without any measurement with instrument as every company does today.

To

make matters worse, there was no air conditioning in whole plant at that

time and we had only steam heater just to make operation area not too cold

to work in winter. Thus, the room temperature was much higher in mid-day and

lower in the morning or late afternoon. This made the components of the

radio sets to expand in day time and contract in the morning or late

afternoon, resulting radio sets had been adjusted differently depending on

the time adjusted during the day, especially in the winter. In spite of this

kind of problems, Gold Star made a lot of money because it was the only

company making radios in

Korea

in those days. That sounds like it was way back to the time when the earth

was created. Isn¡¯t it?

It¡¯s hard to imagine now, but it really was.

I

was the first engineer graduated a university majoring Electrical

Engineering and started to work as an engineer at radio design section,

directly reporting to plant manager with a few other design engineers, who

had been radio repair men at radio shops, without section manager to report.

When I started designing radio, I realized that I didn¡¯t have enough

knowledge to design radio set as I was neither really an electronics

engineer nor electrical engineer, though I had graduated from one of the

best universities in

Korea

. I studied electrical engineering course as the official major but spent

about half of the time to study electronics as the optional subject,

resulting I could not study neither one well enough as I had already

described. However, I couldn¡¯t say I could not do the job and regretted

again that I did not major in communication engineering.

In

addition, I was speechless when the plant manager told me in reply of my

request to purchase about ten books to study about radio design - he said

¡°How can you say you are a good engineer if you have to have all the

things other engineers have.

A good engineer should be able to do well enough even without any

materials or sources, while others have to have everything they need.¡± I

was absolutely stunned and I had no idea how to react to his response. The

Gold Star was thank kind of company at the time !!!

I

had no one to teach me and I had to take apart sample radios made in

Japan

, imitated it and designed radio set for Gold Star somehow. When I asked

some questions to my senior design engineers about designing radios, he

said, ¡°Don¡¯t even think about the theory. If you don¡¯t know how to do

it, just take it apart and do cut and try to find the best way.¡± They had

just ignored the theory and designed radio by their repair experiences only.

And that was the Gold Star then.

Since

I was the only college graduated engineer, I couldn¡¯t just follow the

suggestions of high school graduated repair men. I don¡¯t remember well how

I have designed one model of radio, but I struggled more than a half year

and finally designed the model A-503. But I don¡¯t think it was a

successful model and didn¡¯t sell well in the market.

It

was the beginning of the transitional period of the radios switched from

traditional vacuum tube type to transistor radios and Gold Star was selling

some transistor radios already. Meanwhile, I lived up in one of my fellow

engineer¡¯s house and was busy to go to

Seoul

every weekend for dating. I think I went to

Seoul

more often than many separated married couples are doing these days. As the

Sunday was the only holiday during a week, I usually went to

Seoul

on Saturday night and came home Sunday night, after which I had to go

straight back to work. It was tough dating.

However,

after I got engaged in May 1961, 7 months after I started to work in Gold

Star in September 1960, it was lot easier for me as I could visit her home

openly and stay there whole day. (I didn¡¯t have to find a place outside to

date.) But I still went to

Seoul

to see her almost every week end until I married her in April 1962. (Later

on, there was a sleep train with beds that I could sleep in during the trip

and I wasn¡¯t as tired as I used to be. Instead, I guess I spent quite a

money for train tickets.)

After

I got married in April 1962 and started new life with Jane in a small rented

house with one room in Seomyeon, I was so glad that I didn¡¯t need to go to

Seoul so often and, best of all, I didn¡¯t have to eat Pusan food, which

was really salty and spicy.

Cho and Im family

members at our wedding.

As

Jane had a pharmacist license, we decided to open a small drug store near

home, which was called Sungil Drug Store. Because we spent most of free time

still dating together here and there, the store was kept by a hired

pharmacist without license most of times. Therefore, She could kill times at

the store while I was working at office and I don¡¯t think we have ever

made money.

At

that time, salary was so low and many salary men had to have advanced

payment of salary from the company. I borrowed 30,000 won (Less than $3,000

worth today?) from Gold Star when we started our new life in

Pusan

, which could not be fully repaid until I quit Gold star, repaying some but

advanced again every month.

A

few months later after we have married, Gold Star made a technology contract

with Ziemens of

Germany

to build watt-hour-meter for residents for the first time in

Korea

. As a part of the contract, Gold Star arranged a fund of 1,200,000 dollars

loan from Ziemens for the project. $1,200,000 isn¡¯t a whole lot of money

today, but back then, it was the time that Dong-Myung Wood Company received

a special trophy of ¡°The First One Million Dollars Export

Achievement" from Korean government. So it was a great deal of money

for Gold Star. It was also the time that black and white television

broadcasting was just started in

Korea

and people just began to purchase B/W TV sets.

Gold

Star arranged the contract with Ziemens that 90% of the money should be used

for purchasing various equipment from Ziemens but 10% may be used for

purchasing from other companies. With this 10% or $120,000. fund, Gold Star

made another technology contract with

Hitachi

of

Japan

to produce

Hitachi

TV sets in Gold Star. (confidentially and unofficially to Ziemens and Korean

government, of course)

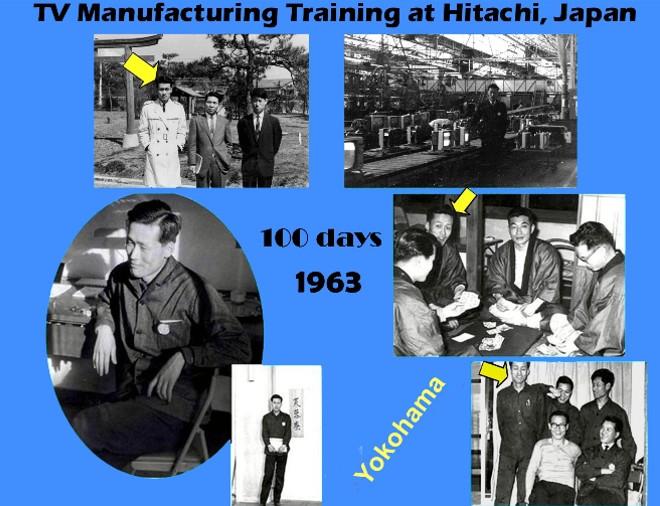

Six

engineers were chosen at Gold Star to go to

Japan

to be trained at

Hitachi

and I was chosen as a member of the team responsible of TV design. I was

released from radios design and started to process passport to travel to

Japan which took more than 6 months due to various government red tapes at

that time. It was the time that only those who were in high positions could

travel abroad and it was more like a dream for fresh college graduate like

me would go abroad. When I was going to get my passport, I kept dreaming of

getting on the airplane every night but I woke up before I could get into

airplane by some reason always.

At

last, I left

Seoul

on 1/3/63 and was trained at

Hitachi

TV Plant in Totsuka, south of

Yokohama

. While I stayed in

Japan

, everything was new to me and color film was just introduced in the market

only few years ago which was still very expensive. I took so many color

pictures there spending more than half of my monthly travel allowance for

such expensive color films.

There

was a really funny story of this trip.

One of our fellow engineer saw latest beautiful lady¡¯s brief at a

shop in Japan, wanted to give it to his wife as a trip gift as that kind of

brief was not available in Korea and bought a few of it. However, he was

shamed to show them to custom inspectors in

Seoul

. Therefore he wore all of these lady's briefs on his underwear when we

returned to

Seoul

. Later he accidentally talked about it and we all couldn¡¯t stop laughing.

After

we returned to

Pusan

from

Japan

, $120,000 worth TV manufacturing equipment from

Hitachi

arrived as the contract we made. However, we had to clear all these

equipment as watt-hour-meter manufacturing equipment through Korean customs

and had to change all descriptions of the equipment on custom papers. We

really had hard time to come up various ideas making up names of TV

manufacturing equipment as if they are watt-hour-meter equipment.

Anyway,

it was the first time that Gold Star had that kind of fancy electronic

measuring equipment and I had a great fun time for a while to play with

these wonderful new equipment. However, very soon, the government suddenly

announced there was no foreign currency in

Korea

to import TV components from other countries and TV manufacturing project

had to be suspended indefinitely. All other five engineers trained in

Hitachi

went back to their original works at the radio departments but I was

assigned to remain at the TV project alone and take care of all these

equipment.

I

started to install new equipment and learned how to use them everyday which

was a great fun for me. However, in about a month, I really didn¡¯t have

much to do. I took even naps in a dark room called the Shield Room which was

one of the imported equipment, all wrapped up in metal without even a window

to prevent any radio wave to penetrate to inside and to be used for

measurement of radio or TV set. It was completely dark when the light was

turned off and was the best place to take a nap.

However, I began to get bored and I couldn¡¯t even take a nap in

about a week. Every morning when I was ready to go to work, I began to worry

about what I was going to do today at the office. I really learned well how

hard it is to spend a day at office doing nothing but paid. I felt like time

had stopped since I didn¡¯t have work to do.

At

last, I came up with the idea that I could measure and create specifications

of all radio models on sale, which Gold Star never even dreamed of.

Since we had the equipment to do it now, I decided to sample all

models from warehouse, measure all specifications and confirm their

performances such as sensitivity (how much weak signal it can catch),

selectivity (how well it can receive desired signal only without

interference of other signals near by) and audio quality etc.. As a matter

of fact, that kind of process should be the first thing to be done after all

of the electric products are made. In other words, before the products are

sold, they should have these kind of specifications attached to the radio

set. But since consumers at that time did not know about the specifications,

Gold Star had no problem selling radios without specifications. And, that

was the first attempt at Gold Star and the beginning of the modernization of

Gold Star radio manufacturing.

One

day, I found a rusty radio out of samples I took from plant warehouse, when

I looked at inside of the cabinet. It looked like it was made a long time

ago. I took them to the plant manager and asked whether we should ship them

or scrap them. He said, ¡°Gold Star is the only company producing radios in

Korea

. Who would care about rust as far as it is working OK. Just ship them.

People will buy them.¡± Gold Star was that kind of company at the time.

This

project to create specifications was over for all models in a few months and

there was nothing more to do again. I think TV manufacturing project had

been delayed for more than 2 years as Gold Star had not been able to produce

TV sets while I was there. Therefore, the next project I came up was Drawing

Control System of Gold Star. At that time, the drawings were called blue

prints developed using Ammonia gas. However, the problem was they were all

in different sizes. Some were as big as a palm, some were twice as big as a

newspaper. They had never been controlled and had no drawing number. Once

the drawing was made and sent by designer to manufacturing, the

manufacturing fixed the problem under the verbal instruction of designer,

whenever there was a problem, without changing the drawing. In addition,

many die sets were worn out producing different parts from the original

drawings. That was the reality of Gold Star in those days. While I was

visiting

Hitachi

, I saw all the drawings were standardized in six sizes and well controlled

with control numbers.

It

was the time when Xerox started copy machines in United States earlier and

¡°Ricoh¡± of Japan introduced ¡°Recopy¡± machine in Japan market not too

long ago, which was just imported by Shindo Ricoh to Korean market.

I

finally persuaded the plant manager to buy a copy machine and assign two

draft men to me, so that I could redraw all drawings scattered here and

there in the company. I reviewed all drawings to confirm each drawing was

exactly same as the actual component, measuring each component with caliper

and micro-meter which can measure 1/100 of 1 mm accuracy. If I found any

discrepancy, I had to discuss with the designer to find which one was right

dimension or had to make own judgment sometimes which one to be corrected

– drawing? or component?. This way, I had redrawn 100% of Gold Star

drawings in 5 different standard sizes (A1 - A5 sizes) to correspond exactly

to each component and numbered each drawing with the new numbering system I

have established, to enable the control of all drawings at one control

center. And, this was the first standardization of the Gold Star Drawing

System and also the first effort of modernization of Gold Star manufacturing

operation.

It

took almost one full year to fix and standardize all drawings in Gold Star,

correcting either dimension figures in the drawing or actual die sets in

machine shop to make the component, which was my job until I quit Gold Star

in 1964. Some Gold Star engineers in later days told me that they wondered

who the person would be after they saw the signature of Dong-In Cho in all

early Gold Star drawings. And, when they found out it was me, they praised

me saying ¡°You are the person who has established the foundation of modern

manufacturing of Gold Star.¡± which made me very proud of myself for what I

had done for Gold Star. During this period, my job was rather easier, as it

took more time of two draft men to draw all the new drawings than I was

checking the actual dimensions and discussed with engineers which dimensions

would be correct.

Since,

it was the time Koreans were generally too poor, especially at operator

level, it was not unusual they took some small components to home and sell

them at market to make extra money. (labor cost was so cheap¡¦ maybe a few

cents an hour, cheaper than

India

today perhaps). To prevent this kind of stealing, most companies checked not

only female operator¡¯s personal belongings but also did a body search when

they pass through the gate after the work and the Gold Star was no

exception.

One

day, a guard asked us to open our lunch box for checking when we go home

through the gate, which drove us crazy because we all had our pride as

college graduated engineers. It was understandable for so many girls but how

could this possible to small number of engineers? If they can not trust even

a few engineers, whom are they going to trust to run the company? All the

engineers were so mad and excited on this company action and got together

immediately at a restaurant in nearby Dongnae to talk about crazy and stupid

company policy in the evening.

Everyone

blamed the management team harshly for their stupid poor policy, who had

damaged their pride so much and some extreme guys called for immediate total

resignation of all engineers. It might not be such a big deal perhaps, if we

could be calm and think objectively. However, these young mad engineers

could not accept the matter at all. Finally, however, we could calm down

little after excited discussion for 2-3 hours and decided every one would

not work at office for next one week.

Actually,

we didn¡¯t say anything but didn¡¯t do anything either. We drew a line on

design paper, erased it, killed time for a while, drew a line again, erased

again¡¦ for whole day. We goofed around for a whole week this way. It was

OK for a day or two. However, it was not easy thing to do for a week, but

very hard one week. Finally, I could not be patient enough and decided to

quit the company, though I felt very sorry to

Director

Park

, the brother of my brother-in-law and who hired me to Gold Star.

These

are the stories about my work in Gold Star for three and half years. I will

just add one more episode I had to finish the story at Gold Star.

One

day, there were visitors from

Hitachi

,

Japan

and we entertained them at a fancy restaurant in Dongnae, where Mr. Jung-Hoi

Koo, the president of Gold Star had attended too. As usual, I sat at a

corner of the table, so that the host will not see me easily as I can not

drink any alcohol at all.

Unfortunately,

President Koo found me not drinking and said, "Hey, what are you doing

there in the corner not drinking?

How can I believe that you are a good engineer if you don¡¯t drink?

Hand in your resignation.¡±

I knew he was joking of course, however, what the hell the drinking

had to do with my job. I was so mad instantly and almost lost my temper but

I could barely hold it down thinking of

Director

Park

.

What

I learned from that event was that people in high positions should never

say, ¡°Hand in your resignation,¡± even if it was just a joke. One more

very important lesson I had learned at Gold Star was that if there is

nothing to do at work, it is better just to send him/her home.

Never make your employee kill his/her time at work.

Of course, to be too busy at work is not too good making him/her to

tired. However, it is even worse to let him/her idled at the company doing

nothing, as it would cause him/her to think about more complains about the

company only.

Trust

in your people always. Trust not only the honesty to prevent theft of

company property, but also trust their ability. They might not be as capable

as you are now but think about yourself as you might not have been as

capable as they are today, when you were at their age. Your absolute trust

in your people will return to you as their absolute respect and trust in

you. There are many people who have to do everything by himself/herself,

because they can not rely on his/her people, which will result nothing but

your busy life and untrained people to work for you, and, most of all, they

will not trust you either.

¡¡

|