Samsung DRAM Quality Improvement

Chart

|

D.I. JOINED SAMSUNG (1986)

D.I. joined Samsung Electronics Co. (SEC) and returned to Korea in late

1986. They lived in Korea for 10 years until they returned to U.S. in 1996.

During this 10 years, D.I. worked 5 years for Semiconductors Division

and another 5 years for Home Appliances Division of Samsung to improve

the Quality of the products and to support customers technically. Then, he

was transferred to U.S. to work at AST Computers in Irvine, California, for a year,

which Samsung acquired and had a serious quality problem and SAS,

Samsung Austin Semiconductors, a new DRAM Wafer Fabrication plant in

Austin, Texas, for about an half year to set up quality system from the start

of the plant, working total of about 12 years for Samsung until he retired in

1998.

D.I. traveled a lot around the world to visit customers to resolve quality

problem and to convince customers about the excellent quality of

semiconductors of Samsung for Semiconductors

Division, and to train employees and set-up Quality System of oversea

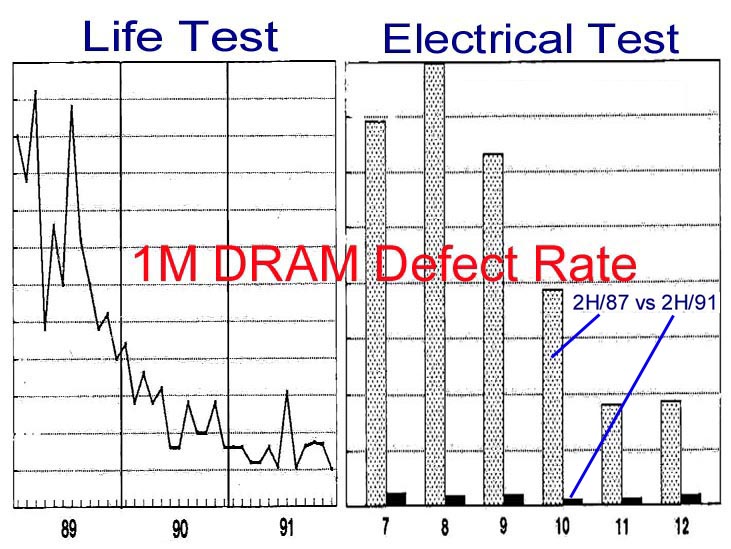

manufacturing plants for Home Appliances Division. Samsung DRAM quality

improved from worst to best in the world since D.I. joined Samsung Semiconductors

Division as shown at the left chart, and Samsung home appliances (TV, VCR, Refrigerator, etc)

quality improved to Japanese products level too since D.I. joined Home

Appliances Division. All D.I. did in both divisions were to set up basic

systems and brain wash people for quality mind, as his philosophy is "Quality

is made by minds not by finger tips", just as he had proven in KMI

and TMI.

Click here to read the Report of SEC

Magazine.

Top : Meeting customers at Kiheung Plant of Samsung Semiconductors

Division. (D.I. at far left)

Center : Training employees of Samsung TV Plant in England showing

problem areas with video he took in their production line.

Bottom : Samsung 1M DRAM Shipping Quality Chart showing improvement.

|