|

¡¡

Semikor

Ltd.

I

quit Gold Star in Pusan

after 3 and half years of service this way and moved back to Seoul

in March 1964 without any new job arranged. How brave I was !! I was

confident I could get a job unless I was too greedy for pay or position. It

was a decision just to live based on my philosophy – ¡°ENJOY

TODAY¡±. I didn¡¯t want to work in a company which I hated and any job

just to survive would be good enough for me as far as the job was

interesteing to work for me.

About

a month after we moved to

Seoul, Willy was born on 4/29/64

and, exactly one month later, father passed away by throat cancer on

5/29/64. He lived painful last few years due to the cancer and visited

Dongsan

Hospital

in

Taegu

by train every month as that was the only hospital equipped with

radioactivity treatment for the cancer in Korea

at the time.

However,

I was lucky enough again that a high school classmate working in Samsung at

the time arranged me a job at ¡°Radio Seoul¡± transmission station, the

first commercial radio station in Korea at that time operated by Samsung

group, as a maintenance engineer of radio broadcasting transmitting

installations. When I worked at Radio Seoul for a year, the President of the

Choong-Ang Tading company whom I have known for about a year approached me

and proposed to work for him to build a TV manufacturing plant for his new

project – TV manufacturing jointly with RCA of U.

S.

A..

Since

manufacturing had been my specialty which interested me always rather than

broadcasting station, I moved to

Choong-Ang Trading Company and built a small TV manufacturing plant with my

knowledge learned in Gold Star and

Hitachi. When the plant was completed in several months, we found out the story was

scheme to get special benefit from government and we had been all cheated by

him.

This

way, my job at Choong-Ang Trading Co. was over in less than a year and I

became jobless again without even the last 3 months of salary paid. I took a

sample TV from RCA (12 inch black and white TV set) instead of 3 months of

salary and quit the job (We became one of the first family with TV set in Korea

instead !!).

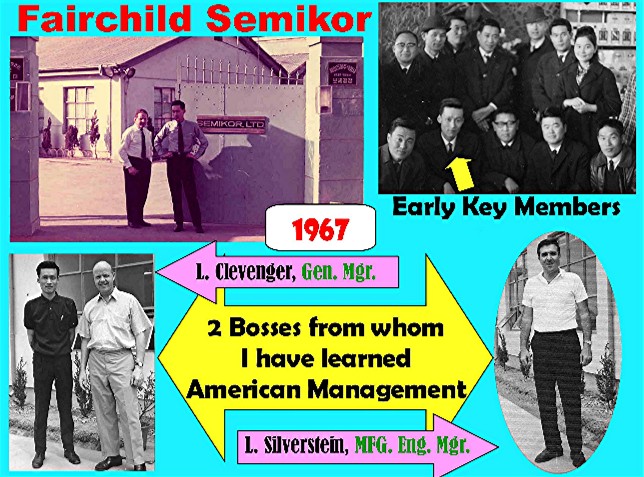

Under

this kind of situation, I was proposed by Mr. Seung-Chan Park

of Gold Star who helped me at

Gold Star, to interview with Fairchild Semiconductors which was just going

to open new assembly plant in Korea. I met Mr. Lyle Clevenger, the General

Manager of Fairchild Korea

(Semikor Ltd.) and this was how I started to work for Ameican Company.

It

was a very important meeting for me to get a job. However, I have never

talked with American in English face to face. The

first experience of mine to

talk in English was I asked to American MP ¡°What time is it now?¡±during

the Korean War when I was 9th. grader in

Pusan, where I worked as a harber

labor and he showed me his watch without any

reply. I was so glad to confirm he could understand my English at least.

After

that experience, when I was in college, I learned German at FLI (Foreign

Language Institute) attached to

Seoul

National

University

for 3 months to prepare to go to Germany

and talked some English with German teacher though we talked German mostlty.

My

English conversation had been developed mostly though the ham radio

actually. I talked with foreign hams every day over the radio. However, all

we talked were just a few sentences such as – ¡°My transmitter is

¡¦.¡± ¡°My receiver is ¡¦¡± ¡° My antenna is ¡¦..¡± ¡°Wheather here

is sunny and warm¡¦.¡± etc. etc.. A few same sentences every day. However,

I found later this is the best way to learn foreign language just as a baby

practices when he learns to talk.

Anyway,

this was all I had experienced to talk English at the time and I had to talk

with American General Manager to get the job!!

I

met Mr. Clevenger at a hotel. In Korean companies, there was no interview

and hired people just looking at resume only rather depending on the person

who introduced the applicant to the company. When they had an interview, it

was a kind of test asking various questions.

However,

American way seemed to be totally different. He explained about the

Fairchild and we talked about various things about Korea – about

society, people, history, geography etc. etc.. It was not really an

interview but a conversation between friends. (Probably he observed me

during this conversation.) We talked for more than 2 hours and I could be

more and more confident on my English as we talked. Finally, he asked me to

wait for the further notice at home.

About

a week later, I got a mail from Mr. Clevenger asking me to come to a hotel

to have a lunch together. (There was no telephone in my home as telephone

was extremely expensive and very hard to get installed.)

I met him and after talking about all kinds of subject of Korea

again for a few hours taking a lunch, he asked me how much salary I want to

get.

In

Korea, it had been a general practice we never talked about salary but found out

on the first pay day after we were hired. As it was the first time to be

asked about salary, I was really surprised and didn¡¯t know what to say.

Since I was asked about it, I had to say something. I instantly figured out

approximately 50% more than what I was paid in Gold Star and Radio Seoul

and asked him it as the amount of salary I wanted.

It

seemed

it was too high from the salary level of Semikor they have planned and he

tried to negotiate the salary. Well, I have never experienced to negotiate

my salary which

must be the value of me

and could not be lowered because

of my pride. We coulod not approach to the agreement for a while (about 30

minutes?) and insisted own ideas each other.

However,

I needed a job desperately and realized I had to compromise somehow.

Therefore, I got an idea and proposed

¡°I don¡¯t know Fairchild and

you don¡¯t know me well each other. Let¡¯s have a trial period for 6

months. 6 months later, if you think I am worthwhile as much as I am asking,

you should adjust my salary to the level I am asking. On the other hand, I

will try to understand the Fairchild for 6 months and will quit the job if I

find it is not the company worthwhile to work any longer.¡±

I

still don¡¯t know how this jobless guy could be that brave and totally

inexperienced salary negotiater could come up with that kind of great idea

instantly. And how could I express all this in English with so poor English

conversation experience.

Any

way, Mr. Clevenger accepted my proposal finally and I was hired after

approximately 4 hours of discussion. I think I had a special talent to be

Americanized accepting their culture easily perhaps, as my first salary

negotiation was quite successful (I think) or I might have been influenced

by my father who had been in U.

S.

A. for college in early years.

This

way, I started to work for Semikor (Semi-conductor Kor-ea) with badge

number 13 and the first job was to translate all Operation Instructions into

Korean language which took a few months untill the first operators were

hired by Semikor. It was not easy to translate all strange terminologies,

such as Die-Attach, Lead-Bond, Lead-Weld etc. etc., which I have never heard

and I didn¡¯t know what those mean, as Semiconductor Assembly Operation

itself was my first experience.

However, I managed the translation somehow with a lot of imaginations and

completed by the time the plant was ready to hire first operators. Now, I

was appointed as the Training Supervisor to train newly hired operators for

2 weeks. I think I got this job because I was talking much and very well

perhaps (???).

When

we started Semikor, all Korean plants had been operated during

8:00 AM – 5:00 PM

without any shift work. Semikor was the first company in Korea

to implement 2 shifts operation, working

6:00 AM – 2:00 PM

and

2:00 PM – 10:00 PM.

There

was a curfew in Korea

at the time between Midnight

and

4:00 AM

. It was not easy to go to the company at

4:00 AM – 6:00

AM

as there was no bus operating at that hour and my home was at Miadong,

northwestern corner of

Seoul

, while Semikor was at the southern corner of Seoul. The only public transportation at that time period was taxi which was too

expensive. We talked about this problem at the second meeting at the hotel

and Mr. Clevenger promised the company will provide transportation to come

to company at early mornig only, as going home at the afternoon was not a

problem. And the company car picked me at home at

5:00 AM

every morning.

After

I worked this way as the Training Supervisor for several weeks and number of

workers were increased to a few hundreds, I learned that the company

provided this kind of transportation to only employees hired at the

beginning (about 10 of them) and all others - supervisors, mechanics,

technicians – had great difficulties coming to company at early

morning without any public transportation. (Operators were OK as they all

lived at cheap lodgings near the

company.)

I

and Young-Il Lee, the Production Supervisor at the time, were eldest seniors

of the group working in the production

area. We went to General Manager¡¯s office one day and proposed the company

to provide the early morning transportation to all shift working people

contracting with a bus company, as it is not a big money considering total

company operation cost.

However,

the answer was ¡°NO¡± because it was not in the ¡°Contract¡± with these

employees, while it was in the ¡°Contract¡± with the first 10

or so people. We

talked for about an hour but the result was absolutely ¡°NO¡±. All we

could get was to learn a new culture of western society which is working by

¡°Logic¡± than ¡°Human Feeling¡±. Instead, if ¡°Logic¡± is right, it

is much easier to convince them than Koreans to whom the FACE

is so importannt which makes very hard to change their

minds

many cases.

The

meeting was over this way. However, we could not just leave the office as

failure. Finally, I said ¡°OK.

Your logic is right. We can not

argue on that. However, in Korea, the ¡°Human Feeling¡± is more important than ¡°Logic¡± in many cases.

Regardless it is right or wrong, this is that kind of society which you have

to know if you want to continue business in Korea. Since

you say ¡°NO¡±, we have no choice but to do our responsibility as seniors.

We will rent the bus and provide transportation to our juniors out of our

salary.¡±

After

this statement, we just came out of the office. On the way back

to my desk, my boss Mr. Lew

Silverstein who joined the meeting but never said anything just listening to

everyone, followed me and showed his hand with thumb up without any word,

which seemed saying ¡°You did great¡±.

I

and Young-Il Lee actually paid bus rent for a month (I am not sure now but

it was about 20% of our

salary perhaps.) However, when I

got next pay check, I just lost my word as THE SALARY WAS INCREASED BY BUS

RENT COST!! Mr. Silverstein was such a great guy!! I was really impressed on

his humanity and, suddenly, he was such a respectable boss to me.

Officially, he could not argue against Mr. Clevenger¡¯s ¡°Logic¡±. But I

saw there one of wonderful American who understand oriental ¡°Human

Feeling¡± too.

After

I worked as Training Supervisor for about 2 months, I was asked to work as

IE. I had never heard about IE and asked ¡°What is IE?¡±. He said ¡°It is

Industrial Engineer.¡±. IE is so popular these days in Korea

too

but it was totally strange area in 1967. Any way, I became an Industrial

Engineer about which I know nothing and another guy took my job of Traning

Supervisor reporting to me in addition to new additional assignment of Line

Maintenance – Production Equipment Maintenance with all mechanics

reporting to me.

With

so many guys suddenly reporting to me, it sounded like a promotion. However,

as there is no titles such as Section Managers or Sub-section Managers in

American companies usually – so many different managers such as Dept.

Managers, Section Managers with hundres or thousands reporting or just one

guy reporting. So different from all Korean companies with these kinds of

titles to show the ranks clearly – I was really confused whether I had

been promoted or took much wider responsibility without any promotion. Well,

what the hell, what does it make difference? The bigger problem was ¡°What

is the IE? and what should this

IE have

to do?¡±

Because

I didn¡¯t know what the IE is exactly, I started to focus Line Maintenance

and Operator Training, which I know what to do.

One day, Mr. Silverstein asked me

to analyze what the maximum production capacity of this plant would be. I

have never learned how to analyze it and he didn¡¯t tell me how to do it.

Well, I didn¡¯t want to say I didn¡¯t know how to do it and just said OK.

I tried to figure out how to calculate it by myself for a few days and

decided to multiply total number of equipment by UPH (Unit per hour –

number of unit produced each hour of each machine) at each process and

figure out the capacity based on the process of the lowest capacity which

should be the bottle neck of the whole line. I calculated it this way and

gave the report to him.

He

looked at it for a while without any comment, took a sheet of paper from his

desk drawer and gave me it. On the sheet, it was the maximum capacity of the

line already calculated by him. He started to educate me how to calculate it

now. He explained we have to give 5% allowance for retard as operators are

getting tired working whole day. We also have to give 3% additional

allowance to the operations requiring microscope as those operators will be

more tired looking through the microscope. etc. etc.

It

would be much easier if he would have explained these factors in advance,

which I would do if I would ask this kind of job to the inexperienced guy,

but he didn¡¯t. Why? He always asked me to do something without education

and explained what I had missed later. However, when he talk about

the problem later, he never blamed me but explained what went wrong very

friendly always. I wondered why he is doing that way.

After

thinking over and over for many days, I have finally came up to the answer.

People get stronger impression and remember much better when he makes

mistake first, realize he has made mistake and learn how to fix it, than he

learn it first and does not make mistake. People also relize the problems

much better while he thinks over and over how to do the job.

¡°Learn

through mistake.¡± This was what he was teaching me, not by kind education

first but by self experience, again!!

He

trained me this way for a few months and by the time I have learned what the

IE is and other jobs too, he called me one day, gave me a few books about

safety of the plant operation and asked me to write ¡°Safety Regulation¡±

of the company. With my limited English knowledge, how long would it take

just

to

read all these books first of all? Several months perhaps. (There was no

Korean company with Safety Regulation in 1967 and I understand safety is

still one of the weakest area of Korean society today too.)

This prestigious guy could not say I could not do it. I took the books and

tried to read them for about a week. However, there was no way I could read

all these books and write Safety Regulation which I have never seen yet.

About a week later, I had no choice but to give up. I went him and said I

could not do it returning all books.

He din¡¯t say anything but smiled, and started to write the regulation by

himself. He came to office at

6:00 AM

and went home at

10:00 PM

working whole 2 shifts hours every day for more than a week, I remember. He

must had iron body and I didn¡¯t know how many hours he slept a day. He

never seemed to be tired nor sleepy at office. I thought it should be the

difference of westerners grown with meats and Koreans with Kimchi, and I

asked Jane

to feed

a lot of meat to our children every day.

Any way, about a

week later, he gave me the draft of Safety Regulation with more than a

hundred pages and asked me to give General Manager¡¯s secretary to type it.

While I was walking to the secretary, I looked at his draft, and when I saw

the last page, I could not help but stopped there. I felt my head was

hammered. There, I saw ¡°PREPARED by

D.

I.

CHO¡± !!!!!!

He

did all this hard work for more than a week and he wrote as if it was

prepared by me. How many people could give honor to others working for him?

I learned instantly a great management which I would never learn from others

during my whole life perhaps.

¡°Give

honor to people working for you and take blame of them yourself, as the

company is usually much more generous to high positions but blame harder for

the mistake of the lower positions. This way, Get the respect and trust of

your people working for you. The result of your organization is achieved by

actual workers always but the honor of success of the organization goes to

you any way.¡±

What

a great and most useful management philosophy it is!!! What a great training

I am getting without paying any tuition or spending a lot of time to learn

it. I realized how lucky guy I am to have this great boss!!! This philosopy

had been permanently implanted in my brain as one of basic philosophy of my

manangement thereafter.

A

few months later, it seemed he felt he had trained me enough. He promoted me

to his position – Manufacturing Engineering Manager - and returned to United States. I became a Dept. Manager in 6 months

since I joined the Semikor with

many additional responsibilities, such as Plant Facility Maintenance,

Safety, Security etc., just about every thing of the manufacturing operation

except Production, Engineering and Quality Control, reporting directly to the General Manager, Mr. Lyle Clevenger.

(I

called our Dept. "MISC. DEPT.)

Mr.

Silverstein was really a great boss for me. He had a magic to make all his

people to respect him. Not only he was the most respectable boss for me, but

the best teacher in my whole life to learn operation as well as management.

I could learn all this logical and reasonable American management skill and

philosophy from him which became

my basic knowledge, operating and managing several plants thereafter. I

believe he should be honored for at least half of my success in various

plant operations in my life and I was really lucky guy to meet him at my

early life.

I

recall it was several weeks after I started to report to Mr. Clevenger. One

day, he came to me and asked me to follow him with pen and paper. We toured

whole plant together and he started to point out every place wrong and to be

corrected. He pointed out more than 150 places (really !!. no exaggeration).

I thought our plant was the best plant in the world but had to relaize it

seemed to be the one of the worst.

In

semiconductor plant, the cleanliness is the key of the operation and there

are dry boxes in front of operators to store raw materials temporarily with

glass windors to prevent the dust to get in which have to be closed all the

time. However, what we found was about one third of the windows were not

fully closed. Since operators had to take out and put in raw materials few

times an hour, they were simply not careful enough to close the windows

fully though they were trained to close them. The problem was how come I

didn¡¯t notice it ???

Also,

there were 3 working stations at each working table with 3 operators working

at each station and each operating line consisted of 5-6 working tables in a

single line. This line was supposed to be a straight line including dry

boxes on them. However, as operators opened and closed dry box windows so

often, none of the dry box line was straight. However, what the Mr.

Clevenger said was ¡°If it is supposed to be straight, it must be straight

always.¡± Yes. It is right logic, sir!! However, we have hundreds of

operators, who must be careful opening and closing dry box windows always

for whole day without exception. Is it possible?

Well,

it was even a easier part. There was a nail on the wall but nothing hanging

there. He asked ¡°What is this nail for?¡± His logic is – if someone

put the nail for a certain purpose, it must be used for that purpose or it

has to be removed.¡± What a crazy logic it was!!

There

was a screw driver on an operator¡¯s working table but no one working

there. He said ¡°The tool should be either in use or stored in the tool

box. It should never be left on the table not used.¡± Oh my god!! There was

a tiny crack on the wall and his complaint was ¡°Why is it not repaired

yet?¡±

Sir,

all you said were definitely right logic. However, none of them would be

harmful either for operation or for product quality directly. Why are we

waisting expensive General Manager¡¯s and Dept. Manager¡¯s times for more

than an hour to find all these detailed and unimportant matters?

Well,

it was the General Manager¡¯s order. What can I do even though I couldn¡¯t

agree with him. I started immediately to retrain all operators and mechanics

to correct everything he pointed out. Also, I myself toured whole production

area several times a day checking the line from his view point.

About

a week later, he came to me and asked to follow him with pen and paper

again. We toured the whole production area again

and he found about 50-60 items to

be corrected yet, though it was far less than the first time.

I

was really upset myself and made my mind to see whether he would win or I

win. I would make him to find nothing!! Never again!! I had concentrated

most of my effort just for this problem and did all I could do almost whole

day every day touring around the line again and again.

About

2 weeks later

(It seemed he gave more time this time intentionally because we could be

strained for short period of time but would return to normal sooner or

later.), We toured again, and this time, there were only less than 10

items he could point out!! It looked like he was really surprised at the

improvement we made in such a short time. Thereafter, I had never been

asked to tour the line again.

Result – I won.

However,

I started to wonder why he did it. From my point of view, it was not

logical, which they are based on, to waist such a great time for which it

would not help operation nor product quality. There must be a good reason

for him to do it. But what is it? I had thought it over and over for a week

until finally I found the answer

by myself.

Semiconductor

requires extremely precise operation always as it is the war against 10

micrometer (1/100,000 mm at that time. It is sub-nanometer - smaller than

1/1,000,000. mm today.) which can be seen only through microscope or

electron microscope. Therefore, it requires constant strain

of everyone in

the operation area which is extremely difficult to continue for 8 haours a

day

every day.

Not

only for operators, it is also almost impossible for supervisors or managers

to observe whether he or she is really strained

at the work always or not.

The only way to know is indirect way observing what he had pointed out

– Are the dry box windows fully

closed always? Are they straight always? Is any tool never left on the table

unused? etc. etc..

If these are all perfectly done, which is practically impossible if you are

not

strained

always, it shows they are all strained

always.

Regardless

how much you educate them, it is really not easy to follow for operators.

The only solution is to make it a habit so that it will be achieved

naturally without any special effort. That was

the

way he had demonstrated this to

me.

Then,

why didn¡¯t he tell me it in advance? I realized this was the same way Mr.

Silverstein did. If he explained me, I would understand it easily but would

forget it easily too. He gave me a strong impression and made me almost mad,

which was strong enough for me never to forget!! What a effective way of

education even though it took several weeks to educate. Some guys might not

think about this as much as I did and this training method might not work. However,

I believe he thought it would work on me. Any way, it definitely worked extremely well to me. I could not help but

respecting him very much thereafter as anothere great teacher of mine and

appreciated his training very much.

One

more episode. Several weeks after the above episode, I submitted a Purchase

Requisition to buy a pound of nail which was noticed by Mr. Clevenger. He

called me and asked what for I am buying a pound of nail. I answered where

to use and he asked how many I would need for the job. I said I would need

only several pieces this time but I have to buy a pound because it is

general practice in Korean market selling by pounds rather than pieces and

it will be much more expensive if we buy only several pieces.

He

started again his typical logic. ¡°If you buy too many more than actually

required, you have to store the excess nails in store room which will add

another item in the store ledger, require additional shelf space in the

store and the time of storeekeeper to manage it, which will add up to the

company operation cost. If you need to buy really for the operation, I will

loan even a million dollars

for you. However, I don¡¯t want to waist even a penny just for one time

convenience only.¡±

What

a great logic!! But what can I do as far as he is the General Manager of the

company

and his logic is always right? I rewrote the requisition just for several pieces.

However,

I was mad again. Should the General Manager concern spending a penny? Well.

OK. If you want, you will get it. I had declared a war against him again in

my mind and started to think over and over to prepare any requisition from

his view point. And

he had never questioned on my requisition thereafter. I

won again.

Mean

time, it became slowly my philosophy also as I had to agree with him in

principle. This is how I have learned very valuable lesson from him.

¡°Spend money to buy anything more valuable than you spend – not only

materials, but also spiritual such as trust, friendship or respect, etc..

Never spend even a penny without getting any valuable return more expensive

than you are paying.¡±

I

believe he was another great teacher for me and I had really appreciated and

respected him through my whole life. And I was really a lucky guy

again to work with these two

great bosses before I was involved in top plant management jobs.

I

worked as the Manager of Manufacturing Engineering Department for about a

year this way. It was a summer day in 1968 when Mr. Clevenger called me and

proposed to work as a Local Sales Manager. At the time, there were many big

and small transistor radio manufacturing companies in Korea. The Gold Star Co. was the largest and most of

other

companies were manufacturing

radios in large volume for export rather than for domestic market.

Semikor

final-tested the assembled transistors for prime products which meets

Fairchild specifications and sold the fall-outs to these Korean radio

manufacturers at cheaper prices.

One

of my college classmate had been working as the Local Sales Manager of

Fairchild who was just scouted by Motorola Korea

and Semikor needed a new Local Sales Manager. He was an engineer but a quite

a capable politician too. He associated with people very well, play well,

and, more than anything, he drunk well which was essential as a salesman in Korea. Compared

to him, I was totally oposite person. I didn¡¯t think anyone in the world

would ever imagine I could be a sales man, because I could not drink alcohol

at all first of all. When I was

proposed to work for Local Sales, my immediate answer was ¡°No Thanks¡±. I

said ¡°I do not fit to sales job and it will be more harmful than useful

for local sale.¡± However, he insisted to take the job as he did not need a

sales man but a sales engineer and I was

the only one he could

think of to do the job well enough as far as he knew.

In

addition, he sugar coated the proposal saying my sales expense

account would be open without any limit and I would get a sales car with

driver, all company paid. At the time, I was only 33 years old.

And there was no

privately owned car but company cars only for presidents or directors

in Korea at that time and no

one at that age could have a company car.

Most

of all, the offer to give a company car was the most attractive condition

for me. How nice if I could use company car at the age of 33. Finally I had

accepted offer with one condition – My position of Manufacturing

Engineering Dept. Manager should be left vacant for next 3 months and I will

continue sales job only if I could sell anything within 3 months. If I can

not sell in 3 months, I will return to Manufacturing Engineering..

I

accepted the

new job this way just because the

company car was so attractive. I toured all customers with my classmate

before he leave for Motorola Korea

and my crazy sales job was started. At the time, all bars or night clubs

were at Moogyodong

of downtown Seoul. As I knew I have to entertain customers at these places often, I had to go

there almost every other day with

customers.

At

that time, if we went to the bar or night club, there were plenty of girls

working there and girls sat with customers one for one. I gave a special tip

to the girl beside me in advance and asked her to drink my glass too. Then

she drunk my drink carefully not to be noticed

by my customers and left empty glass in front of me as if I emptied the

glass. I acted as if I drunk too much later when it was the time to act. It

looked like my act was not too bad as some customers thought I am a good

drinker even after a year. Any way, I did very hard sales job to me this

way.

About

2 months had passed this way when the Taehan Electric Wire Co., one of big

customer, had to place a large order of transisters - $300,000. worth. The

total transistor market at the time was something like $1,000,000. and

$300,000. order was so huge – 30% of annual sale of total market.

Naturally, big competetion between Fairchild and Motorola had started and we

were lowering price each other by a penny every time, from 35 cents for a

set of 5 transistors plus 1 diode, all the way down to 26 cents.

Since

we could not continue this endless price reduction any further, I proposed

to the Plant Manager, who was our senior of Engineering College of Seoul

National University, to introduce me to the president of Taehan Electric

Wire Co., as the Plant Manager was so indecisive and could not make any

decision. He agreed and we went to head office of Taehan Electric Wire Co.

at the down town Seoul

together and met the president of the company, Mr. Kyung-Dong Sul.

I

don¡¯t remember how old he was

then. To a guy at the early 30s, he looked

like very old man. I explained what had happened in the past and said ¡°I

can not lower the price any further. If you give a price you want and it is

acceptable to me, I will take the order. If it is too low, I will give up

and you may place the order to Motorola. I just want your final price to buy

from us.¡±

What

a surprise. I would never forget his statement and his face. He said ¡°I

can not believe how a guy worked and get paid by Fairchild until recently,

can betray Fairchild next day, compete against Fairchild and lower the price

that much!! What kind a guy he is? Plant Manager, do you think I am a blood

sucker of American people? I don¡¯t rust that kind of traitor. I don¡¯t

care the price. Just order it to Fairchild immediately!!"

Wow!! The Plant Manager didn¡¯t know how to respond and just said ¡°Yes,

Yes, Yes Sir.¡± And we came out from his office.

That

was the ethics of old Koreans at the time. Even we at the ages of 30s and

40s were not familiar to it and could not help but just surprising. We went

to Taehan Electric Wire plant directly from there and I could return to my

office with $300,000. worth order sheet in my hand, which was the first

order I took. Now, I had no choice but to continue sales job as I had

promised to Mr. Clevenger.

I

continued my Local Sales job for about one and half years this way. Mean

time, I had lot of hard times at the bars and night clubs, but had great fun

times too. As I was changed to sales job, Mr. Clevenger was no longer my

boss and I reported to Mr. Lyle Ronald in Fairchild Fareast Sales office in Tokyo. He was an Australian speaking somewhat strange Australian English but

wonderful nice boss for me again. (I was always so lucky to meet nice guys.)

He sent me telex almost once a quarter asking me to come to Tokyo. However, since it took almost a month to get entry visa for Japan but only

a day or two to get visa to Hong Kong, I always got the visa to Hong Kong

first and got transit visa to Japan which also could be obtained in a day.

As

I went to

Hong Kong

without any purpose, I just spent a few days there relaxing with Fairchild

sales men and old manufacturing friends whom

I had met there earlier while I was

Manufacturing Engineering Manager. (There was another Fairchild assembly

plant in

Hong Kong

.)

When

I went to Tokyo

through Hong Kong, all I had to do was just to visit few Japanese companies

who place orders of transistor radios to our customers in

Korea

with Lyle for a few days and return home. In the evening, he usually took me

to most expensive

restaurants and paid by credit cards. He gets real receipts as well as

credit card slip too. He used his credit card slips to submist his expense

report to the company and gave me real receipt to use it to submit my expense

report in Korea which will be evantually approved by him. This way, I could

make $100-$200 in free which he asked me to buy gifts

from Japan for my wife. His logic was – as salesman has to work with customers any time

during the day, even at midnight, I have to make my wife always happy so

that I can always concentrate to the job. Wonderful logic!! Why not?

Since

my expense report will be approved by him any way, I had no reason to worry

and spent quite a compny money for family, taking Jane

and friends to very expensive

high class restaurants from time to

time. This might be one of the reasons why Fairchild had a big problem to be

almost bancrupt, but I understand most American companies are very generous

to salesmen usually for their expenses.

Because

both my bosses in Japan and Korea were all so generous to me, we really had

lot of fun times travelling around whole Korea with company car with family

and friends, went top class restaurant like Walker Hill and brought various

gifts from Japan and Hong Kong which were not usually available in Korea at

that time.

I

always carried several 100,000 won bank notes always and

spent quite a money. Gold Star

was our biggest customer and my classmates working there at Radio Design

Room sent me telex asking me to come to Pusan

from time to time as if there is a problem. However, their problem was

nothing but they want to have a drink at Dongnae

geisha house. I flew down to Pusan, took them to Dongnae

and the problem was solved many

cases.

Because

of this kind of experience together with my philosophy of ENJOY TODAY, I

think it has become partially my habit to spend money too easily even now. Though

I spent

company money well, still, I believe I have spent far less than what my

classmate had

spent as a Fairchild salesman as he really loved to drink at expensive

bars and night clubs while I hated to go that kind of places.

While

I was working for sales, I also learned a lot of things. I learned the

economy of the semiconductor market how it would cycle every few years.

However, the most important thing I had learned was, though many Koreans

would not believe it, HONESTY and SINCERITY are the

key of the sales rather than great entertainment, as most of Koreans think.

Motorola

had a wide beautiful carpeted sales office in downtown Seoul

with a

very pretty secretary sitting there. My office was a small corner in

the plant

very next to the Production Control office. I received Daily Production

Report every morning and checked all the numbers by myself every day. I knew

which products would be exactly available today or tomorrow always while my

classmate at Motorola was sitting at the downtown office communicating with

plant Production Control far a way over the phone. He had no choice but to

depend on whatever Production Control said over the phone. Therefore, he

missed the delivery commitments from time to time, but I never did.

Whenever, there was a production problem and I sensed the delivery might be

very dificult to meet, I discussed with Production Control and changed

production schedule some times as much as we could to make sure our

committed delivery could be met. If it seemed to be inevitable even with our

best efforts, I had informed to the customer well in advance so that the

customer could be well prepared for the problem.

If

there were any quality problem on our product, I informed the problem

honestly to customers as early as

possible so that our customers can adjust to the problem, while Motorola

tried to hide the problem as much as possible and had to shut down customer

lines sooner or later. I could get always strong trust of customers while

Motorola lost their faith from customers slowly. In 1969, the sencond year

of my sales job, I could sell $950,000. which was approaximately 95% of

total Korean market while Motorola could sell only less than 5%. This lesson

of customer service with HONESTY and SINCERITY had been fully utilized at

Samsung later also and made great contribution to Samasung sales.

I

worked at Fairchild Semikor for 3 years and 3 months and left Semikor in

Feb. 1970 to join KMI. Semikor was my best school which I would never forget

for my whole life. What I have learned in Semikor was so useful for my

success at KMI plant, TMI plant in Taiwan

and Samsung plants later throughout whole my life and became my fundamental

management philosophy.

|